Description

A limit switch is an electromechanical device that detects the physical movement or position of mechanical components in industrial electric power systems. It operates by making or breaking an electrical contact when an object comes into contact with its actuator—enabling automation, safety control, and feedback functions in power distribution and machinery.

Limit switches are widely used to monitor circuit breaker positions, control mechanical interlocks, and detect the open/closed state of equipment in substations, switchgear, MCC panels, and automated control systems.

Limit switches are essential in medium-voltage (MV) and low-voltage (LV) electrical equipment, helping ensure safe and automated operation of mechanical devices.

Typical industrial applications:

- Circuit breaker position indication (open/close)

- Power switchgear interlock systems

- Draw-out mechanism detection in motor control centers (MCCs)

- Transformer tap changer monitoring

- Overhead crane position sensing

- Valve open/close feedback in power plants

- Conveyor system position control

- Solar tracking and wind turbine alignment

Key Features of Industrial Limit Switches

| Feature | Benefit for Power and Automation Systems |

| Mechanical Contact Design | Ensures reliable signal feedback and circuit control |

| Wide Operating Voltage Range | Typically 24V–250V AC/DC |

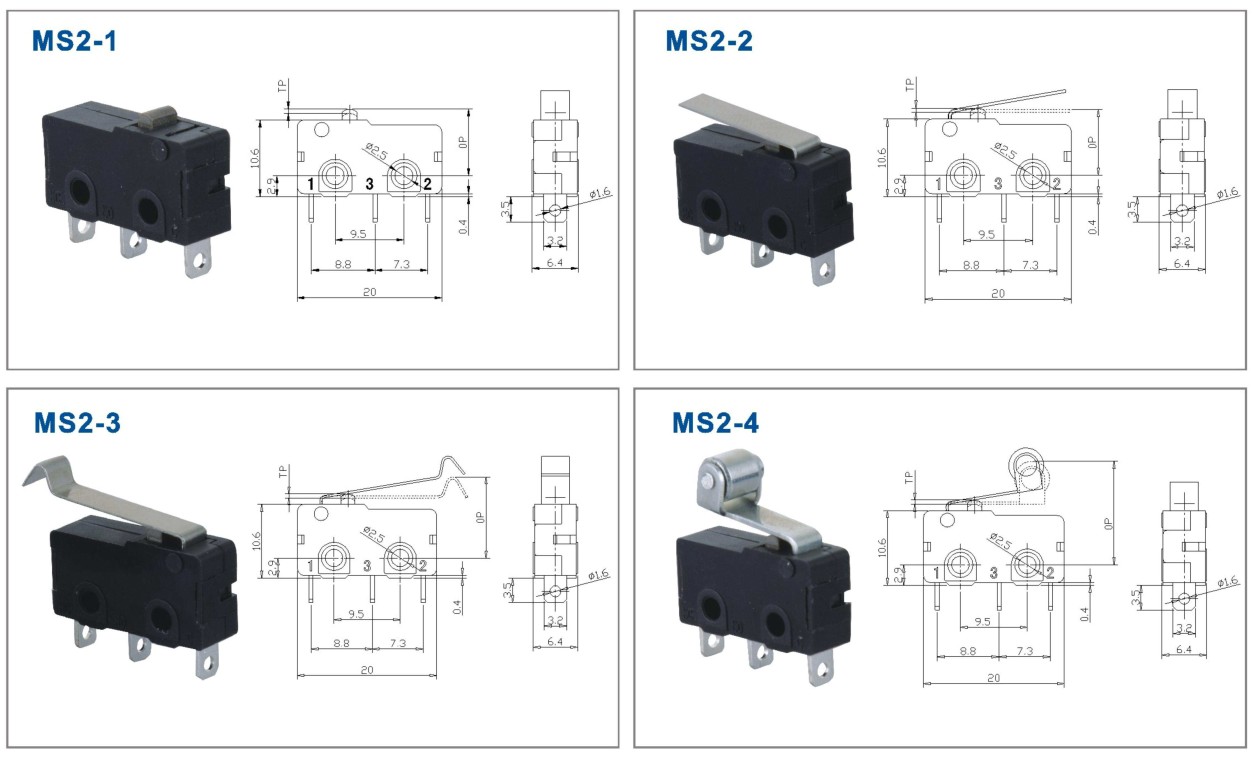

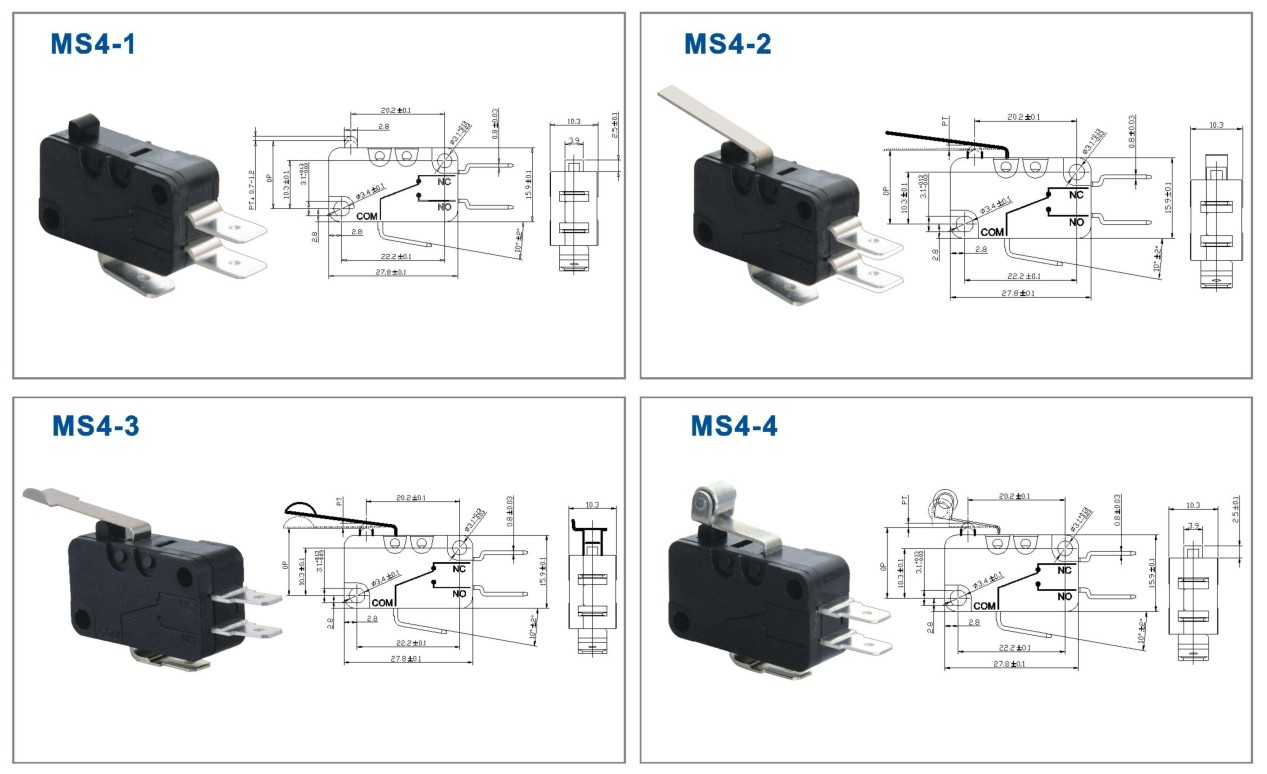

| Multiple Actuator Types | Plunger, roller, lever, spring, or rotary arm options |

| IP-Rated Enclosures | IP65/IP67 protection against dust and water in harsh environments |

| Compact and Rugged Construction | Withstands vibration, shock, and high-cycle operations |

| NO/NC Contact Options | Supports both normally open and normally closed applications |

| Long Mechanical Life | Rated for millions of actuations |

| Standards Compliance | Meets IEC 60947-5-1, CE, and UL requirements |