Mettz

DH Oil single phase

DH Oil single phase transformer with amorphous alloy core produced by our company adopts new magneto conductive material, i.e. amorphous alloy core. It is the most ideal distribution transformer in energy saving at present, especially suitable for the rural power grids and the developing districts, where the load factor is rather low.

In order to meet the various demands of customers, the Company has design D11-M and DH15-Mtwo series single phase fully-sealed transformer. D11-М transformer adopts laminated core and is characterized by low loss, low noise level and others: DH15-M transformer adopts amorphous alloy core which further reduces the no-load losses of the transformer. Table below specifies technical parameters and dimensions of the two series of transformers.

SBH15 Oil Transformer

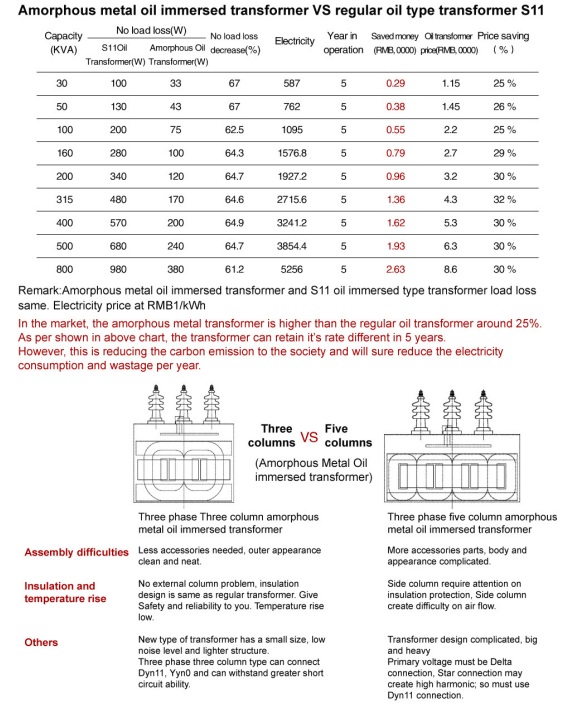

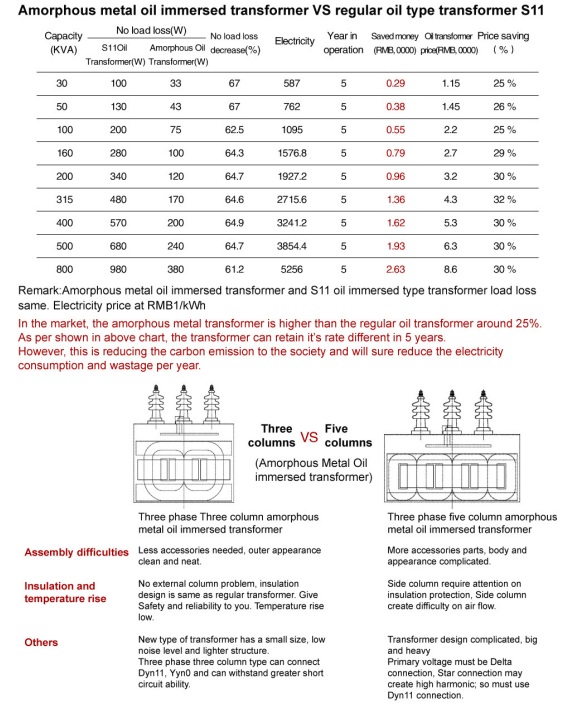

SBH15 transformer with amorphous alloy core produced by our company adopts new magneto conductive material, i.e. amorphous alloy core. It is the most ideal distribution transformer in energy saving at present, especially suitable for the rural power grids and the developing districts, where the load factor is rather low. The amorphous alloy cored power transformer has advantage of low no-load loss, energy-saving and environment-protection, and it is fully in accordance with the national industrial policy ”resource-saving, environmentally-friendly, and the establishment of reef society". In the past twenty years, it has been wildly used in domestic and foreign power grids.

Working conditions:

- Altitude: ≤2000m

- Maximum environmental temperature:

- Maximum annual average temperature

- Customized products are available.

Performance characteristics:

- The core adopts amorphous alloy as conductive material. It’s an amorphous strip alloy treated by rapid cooling and spray process, with iron boron as raw material. Because of properties of soft magnetic and narrow hysteresis loop area, the amorphous alloy only needs a small magnetic power, so transformer made of amorphous alloy has low no-load loss.

- The transformer core use amorphous alloy wrapped with strip three phase five column type structure, which makes the height of transformer is lower than that of with three phase three column type structure. With rectangular core section, its lower yoke can be opened for installing coil easily

- Low voltage winding usually adopts copper foil winded cylindrical structure except of using copper conductor for small capacity ones. High voltage winding uses multi-layer cylindrical structure, which makes a balance ampere-turns distribution, small magnetic-leakage loss, strong mechanical strength and good anti-short circuit ability.

- The apparatus body assembly, tank structure, protection function are totally similar with that of sealed oil type amorphous alloy distribution transformer, which also adopted no-hanging heart structure. The transformer uses vacuum drying, vacuum oil filter-injection process. Corrugated tank, no oil storage tank structure.

- The load loss of his kind of transformer is the same with S9 series, while the no-load loss of SBH15 transformer is 75% lower than that of S9 series; the no-load loss of SBH16 transformer is 80% lower than that of S9 series.

- No need to change oil in normal operation, which greatly reduces the transformer maintenance cost and prolong the life.

- It’s possible of recovering costs increased than silicon steel corer transformer in four year, after calculation for annual power consumption, annual power loss cost and annual electricity charge saving.

S11 Oil Distribution Transformer

Cubic-type Substation S11 oil-immersed transformer has the characteristics of low loss, low noise and no suspension of the core, realizing the four-remote functions of "remote communication, remote measurement, remote adjustment and remote control". It can be remotely controlled by computer, realizing unmanned watching of the substation. Its safety, reliability and economy etc. are greatly improved.

1. Energy conserving

Compared with the original S9 type, no-load loss of S11 decreases by 10.25% averagely, no-load current decreases by 37.9%, and the running expense decreases by 18.9% averagely.

2. High reliability

Structurally improve the effective supporting of both HV and LV coil end faces, adopt the new body location structure. Expand the application scope of the cylindrical coil, and adopt a series of new material, new subassembly, new fastening pieces and new process to make both the performance of the product and structure reach up to higher level, improve the running reliability of the product.

3. The service life is prolonged

Compact structure, small volume, low noise, high efficiency and steady performance of S11 series of transformers prolong the service life of transformers.

S11 series of oil-immersed transformers produced by our company are low loss series of products that have international advanced level. The energy conserving effect is significant. They can be widely used in urban and countryside industrial and agricultural power grid. The iron core adopts the new process of the stepping lamination, resulting in improvement in no-load performance and reduction in noise.

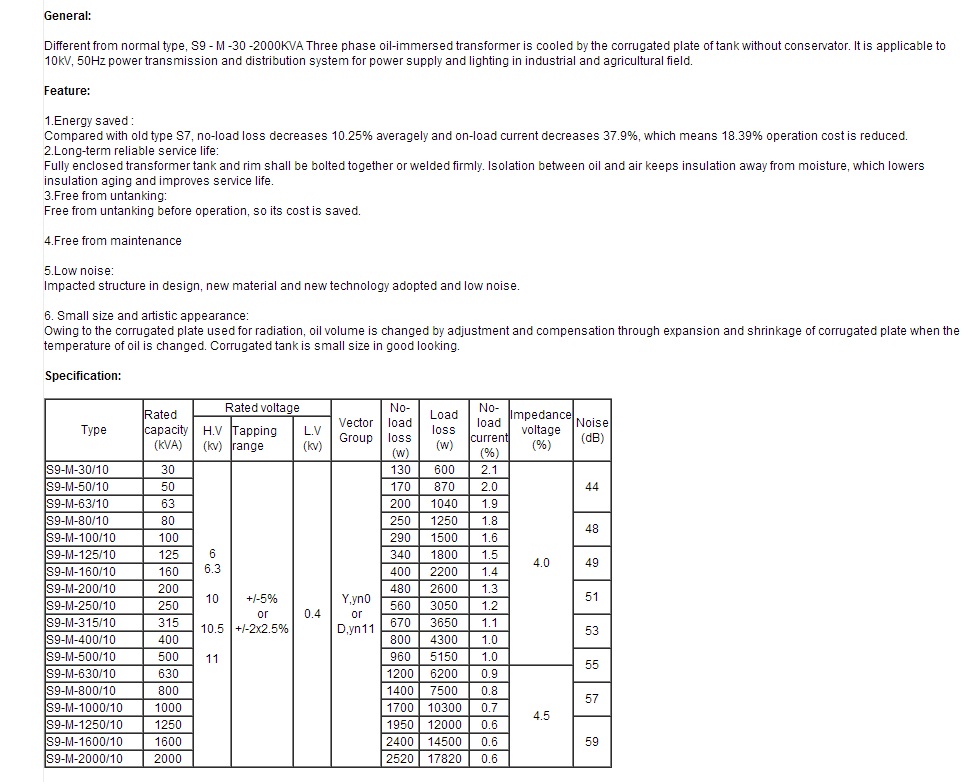

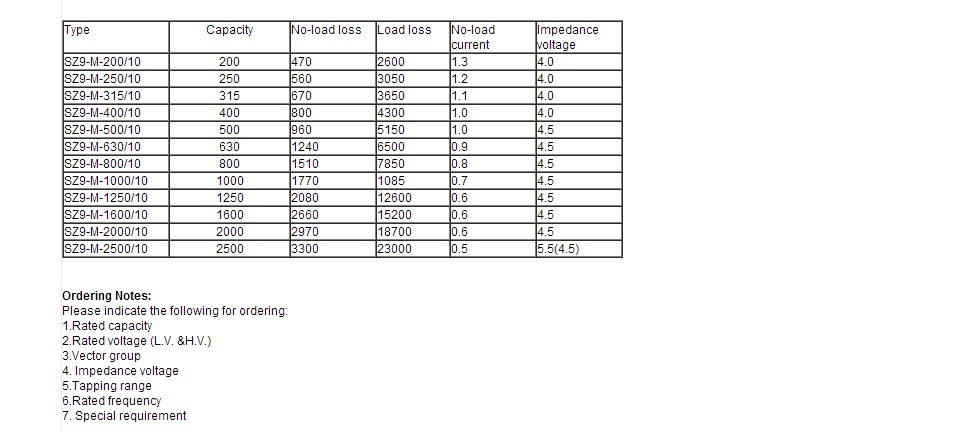

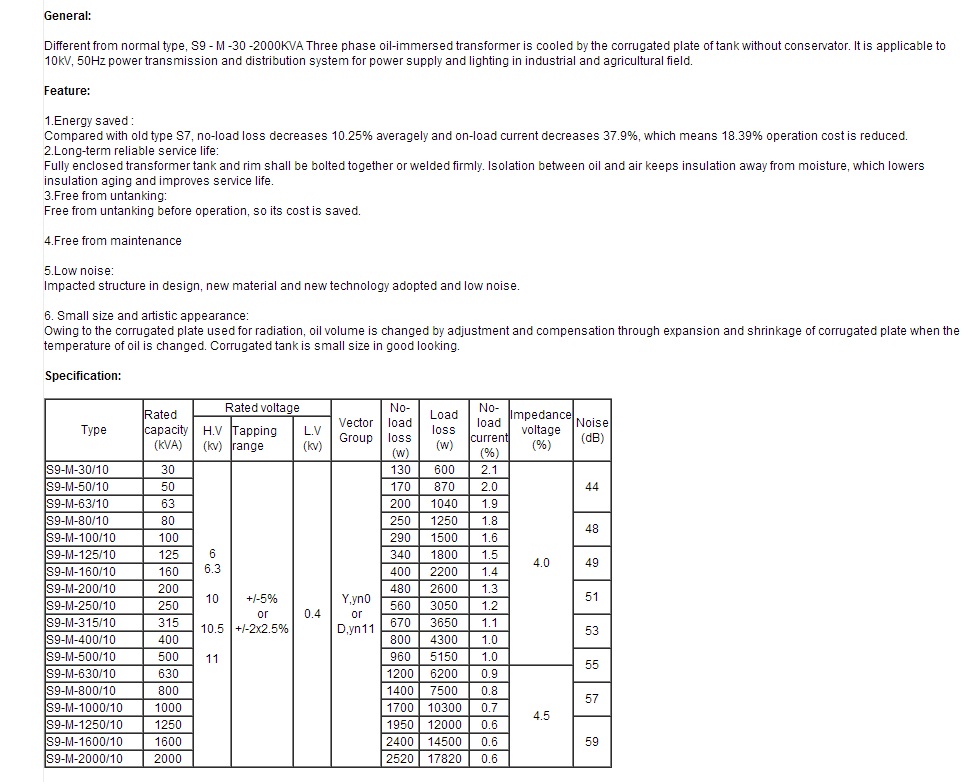

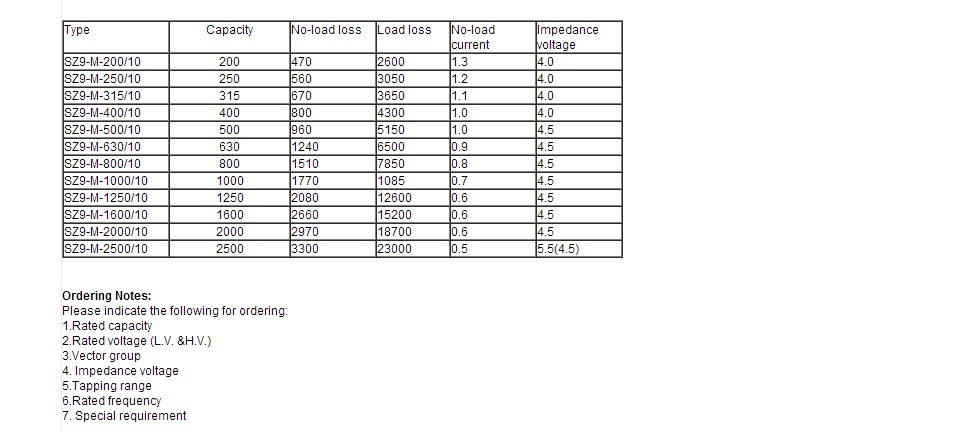

S9 Oil Immersed Transformer

S9 series oil immersed distribution transformer is suitable for 3.6kV up to 40.5kV power class. These series of distribution transformers is oil-immersed with power rating from 25 to 2500 kVA at 50/60 Hz power transmission and distribution system for power supply and lighting in industrial and agricultural field.

Scheme and connection group of windings is optional: Dyn0,Dyn5,Dyn11,YY0 etc. according to customer demand it is possible to make transformers with different connection of the Voltages and other construction solution.

Service environment:

- a) Air temperature: Maximum temperature: +40℃; Minimum temperature: -25℃.

- b) Humidity: Monthly average humidity 95%; Daily average humidity 90%.

- c) Altitude above sea level: Maximum installation altitude: 2500m.

- d) Ambient air not apparently polluted by corrosive and flammable gas, vapor etc.

- e) No frequent violent shake.

Features:

1. Energy saved: Compared with old type S7, no-load loss decreases 10.25% averagely and on-load current decreases 37.9%, which means 18.39% operation cost is reduced.

2. Long-term reliable service life: Fully enclosed transformer tank and rim shall be bolted together or welded firmly. Isolation between oil and air keeps insulation away from moisture, which lowers insulation aging and improves service life.

3. Free from untanking: Free from untanking before operation, so its cost is saved.

4. Free from maintenance

5. Low noise: Impacted structure in design, new material and new technology adopted and low noise.

6. Small size and artistic appearance: Owing to the corrugated plate used for radiation, oil volume is changed by adjustment and compensation through expansion and shrinkage of corrugated plate when the temperature of oil is changed. Corrugated tank is small size in good looking.

Drop-off Fuse

Drop-out fuse cutout and load switching fuse cutout are of outdoor used high voltage protective device. They are connecting with incoming feeder of distribution transformer or distribution lines it mainly protect transformer or lines from shod circuit and overload. And on/off loading current. Drop out fuse cutout is composed of lnsulator supports and fuse tube. Static contacts is fixed on two sides of insulator support and moving contact jS installed on two ends of fuse tube.

Fuse tube is composed of inside arc-extinguishing tube, outer phenolic compound paper tube or epox glasstube. Load switching fuse cutout provides enforedelastic auxiliary con.

Al normally working via fuse link tightened the fuse tube is fixed to form up of close position. 1n case system occure faults, fault current result in fuse melt immediately and take place electric arc.

Guishing tube being heated and explode a lot of gas. This will produce high pressure and blow off the arc along with tube. After fuse link melt moving contact has no tightened shrength again, mechanism is locked and fuse tube drop out. Cutout now is in open position.

When it needs to switch-off during cutout loading, operator shall via insulating operating bar pull the moving contact, at its beginning main contact and auxiliary static contact is contacted still. Whiling pulling the auxiliary contact is separated between auxiliary contacts there occur electric arc and the arc will be length in arc extinguishing enclosure gap and meanwhile arc-extinguishing explode gas to blow off the arc during current passing zero.

Lightning Arresters

A lightning arrester is a device used on electrical power systems and telecommunications systems to protect the insulation and conductors of the system from the damaging effects of lightning. The typical lightning arrester has a high-voltage terminal and a ground terminal. When a lightning surge (or switching surge, which is very similar) travels along the power line to the arrester, the current from the surge is diverted through the arrestor, in most cases to earth.

In telegraphy and telephony, a lightning arrestor is placed where wires enter a structure, preventing damage to electronic instruments within and ensuring the safety of individuals near them. Smaller versions of lightning arresters, also called surge protectors, are devices that are connected between each electrical conductor in power and communications systems and the Earth. These prevent the flow of the normal power or signal currents to ground, but provide a path over which high-voltage lightning current flows, bypassing the connected equipment. Their purpose is to limit the rise in voltage when a communications or power line is struck by lightning or is near to a lightning strike.

If protection fails or is absent, lightning that strikes the electrical system introduces thousands of kilovolts that may damage the transmission lines, and can also cause severe damage to transformers and other electrical or electronic devices. Lightning-produced extreme voltage spikes in incoming power lines can damage electrical home appliances.

Type: zinc oxide arrester

Specifications:

- MOA rated voltage: 24kV

- MCOV: 19.5kV

- 1/4μs steep current impulse: 82kV

- 8/20μs lightning current impulse: 72kV

- 30/60μs switching current impulse: 62kV

- 2ms rectangular current impulse withstand: 150A

- 4/10μs high current impulse withstand: 65kA

Withdrawable trolley

Service trolley

Service trolley used for switchgears series KYN28-12 voltage 3 ~ 35 кВIEC 298.

It is best solution for VCB series VZN63-12 (VS1).

CKJ5-600A-1.14kV

CKJ5-250A-1.14kV

Mettz

DH Oil single phase

DH Oil single phase transformer with amorphous alloy core produced by our company adopts new magneto conductive material, i.e. amorphous alloy core. It is the most ideal distribution transformer in energy saving at present, especially suitable for the rural power grids and the developing districts, where the load factor is rather low.

In order to meet the various demands of customers, the Company has design D11-M and DH15-Mtwo series single phase fully-sealed transformer. D11-М transformer adopts laminated core and is characterized by low loss, low noise level and others: DH15-M transformer adopts amorphous alloy core which further reduces the no-load losses of the transformer. Table below specifies technical parameters and dimensions of the two series of transformers.

SBH15 Oil Transformer

SBH15 transformer with amorphous alloy core produced by our company adopts new magneto conductive material, i.e. amorphous alloy core. It is the most ideal distribution transformer in energy saving at present, especially suitable for the rural power grids and the developing districts, where the load factor is rather low. The amorphous alloy cored power transformer has advantage of low no-load loss, energy-saving and environment-protection, and it is fully in accordance with the national industrial policy ”resource-saving, environmentally-friendly, and the establishment of reef society". In the past twenty years, it has been wildly used in domestic and foreign power grids.

Working conditions:

- Altitude: ≤2000m

- Maximum environmental temperature:

- Maximum annual average temperature

- Customized products are available.

Performance characteristics:

- The core adopts amorphous alloy as conductive material. It’s an amorphous strip alloy treated by rapid cooling and spray process, with iron boron as raw material. Because of properties of soft magnetic and narrow hysteresis loop area, the amorphous alloy only needs a small magnetic power, so transformer made of amorphous alloy has low no-load loss.

- The transformer core use amorphous alloy wrapped with strip three phase five column type structure, which makes the height of transformer is lower than that of with three phase three column type structure. With rectangular core section, its lower yoke can be opened for installing coil easily

- Low voltage winding usually adopts copper foil winded cylindrical structure except of using copper conductor for small capacity ones. High voltage winding uses multi-layer cylindrical structure, which makes a balance ampere-turns distribution, small magnetic-leakage loss, strong mechanical strength and good anti-short circuit ability.

- The apparatus body assembly, tank structure, protection function are totally similar with that of sealed oil type amorphous alloy distribution transformer, which also adopted no-hanging heart structure. The transformer uses vacuum drying, vacuum oil filter-injection process. Corrugated tank, no oil storage tank structure.

- The load loss of his kind of transformer is the same with S9 series, while the no-load loss of SBH15 transformer is 75% lower than that of S9 series; the no-load loss of SBH16 transformer is 80% lower than that of S9 series.

- No need to change oil in normal operation, which greatly reduces the transformer maintenance cost and prolong the life.

- It’s possible of recovering costs increased than silicon steel corer transformer in four year, after calculation for annual power consumption, annual power loss cost and annual electricity charge saving.

S11 Oil Distribution Transformer

Cubic-type Substation S11 oil-immersed transformer has the characteristics of low loss, low noise and no suspension of the core, realizing the four-remote functions of "remote communication, remote measurement, remote adjustment and remote control". It can be remotely controlled by computer, realizing unmanned watching of the substation. Its safety, reliability and economy etc. are greatly improved.

1. Energy conserving

Compared with the original S9 type, no-load loss of S11 decreases by 10.25% averagely, no-load current decreases by 37.9%, and the running expense decreases by 18.9% averagely.

2. High reliability

Structurally improve the effective supporting of both HV and LV coil end faces, adopt the new body location structure. Expand the application scope of the cylindrical coil, and adopt a series of new material, new subassembly, new fastening pieces and new process to make both the performance of the product and structure reach up to higher level, improve the running reliability of the product.

3. The service life is prolonged

Compact structure, small volume, low noise, high efficiency and steady performance of S11 series of transformers prolong the service life of transformers.

S11 series of oil-immersed transformers produced by our company are low loss series of products that have international advanced level. The energy conserving effect is significant. They can be widely used in urban and countryside industrial and agricultural power grid. The iron core adopts the new process of the stepping lamination, resulting in improvement in no-load performance and reduction in noise.

S9 Oil Immersed Transformer

S9 series oil immersed distribution transformer is suitable for 3.6kV up to 40.5kV power class. These series of distribution transformers is oil-immersed with power rating from 25 to 2500 kVA at 50/60 Hz power transmission and distribution system for power supply and lighting in industrial and agricultural field.

Scheme and connection group of windings is optional: Dyn0,Dyn5,Dyn11,YY0 etc. according to customer demand it is possible to make transformers with different connection of the Voltages and other construction solution.

Service environment:

- a) Air temperature: Maximum temperature: +40℃; Minimum temperature: -25℃.

- b) Humidity: Monthly average humidity 95%; Daily average humidity 90%.

- c) Altitude above sea level: Maximum installation altitude: 2500m.

- d) Ambient air not apparently polluted by corrosive and flammable gas, vapor etc.

- e) No frequent violent shake.

Features:

1. Energy saved: Compared with old type S7, no-load loss decreases 10.25% averagely and on-load current decreases 37.9%, which means 18.39% operation cost is reduced.

2. Long-term reliable service life: Fully enclosed transformer tank and rim shall be bolted together or welded firmly. Isolation between oil and air keeps insulation away from moisture, which lowers insulation aging and improves service life.

3. Free from untanking: Free from untanking before operation, so its cost is saved.

4. Free from maintenance

5. Low noise: Impacted structure in design, new material and new technology adopted and low noise.

6. Small size and artistic appearance: Owing to the corrugated plate used for radiation, oil volume is changed by adjustment and compensation through expansion and shrinkage of corrugated plate when the temperature of oil is changed. Corrugated tank is small size in good looking.

Drop-off Fuse

Drop-out fuse cutout and load switching fuse cutout are of outdoor used high voltage protective device. They are connecting with incoming feeder of distribution transformer or distribution lines it mainly protect transformer or lines from shod circuit and overload. And on/off loading current. Drop out fuse cutout is composed of lnsulator supports and fuse tube. Static contacts is fixed on two sides of insulator support and moving contact jS installed on two ends of fuse tube.

Fuse tube is composed of inside arc-extinguishing tube, outer phenolic compound paper tube or epox glasstube. Load switching fuse cutout provides enforedelastic auxiliary con.

Al normally working via fuse link tightened the fuse tube is fixed to form up of close position. 1n case system occure faults, fault current result in fuse melt immediately and take place electric arc.

Guishing tube being heated and explode a lot of gas. This will produce high pressure and blow off the arc along with tube. After fuse link melt moving contact has no tightened shrength again, mechanism is locked and fuse tube drop out. Cutout now is in open position.

When it needs to switch-off during cutout loading, operator shall via insulating operating bar pull the moving contact, at its beginning main contact and auxiliary static contact is contacted still. Whiling pulling the auxiliary contact is separated between auxiliary contacts there occur electric arc and the arc will be length in arc extinguishing enclosure gap and meanwhile arc-extinguishing explode gas to blow off the arc during current passing zero.

Lightning Arresters

A lightning arrester is a device used on electrical power systems and telecommunications systems to protect the insulation and conductors of the system from the damaging effects of lightning. The typical lightning arrester has a high-voltage terminal and a ground terminal. When a lightning surge (or switching surge, which is very similar) travels along the power line to the arrester, the current from the surge is diverted through the arrestor, in most cases to earth.

In telegraphy and telephony, a lightning arrestor is placed where wires enter a structure, preventing damage to electronic instruments within and ensuring the safety of individuals near them. Smaller versions of lightning arresters, also called surge protectors, are devices that are connected between each electrical conductor in power and communications systems and the Earth. These prevent the flow of the normal power or signal currents to ground, but provide a path over which high-voltage lightning current flows, bypassing the connected equipment. Their purpose is to limit the rise in voltage when a communications or power line is struck by lightning or is near to a lightning strike.

If protection fails or is absent, lightning that strikes the electrical system introduces thousands of kilovolts that may damage the transmission lines, and can also cause severe damage to transformers and other electrical or electronic devices. Lightning-produced extreme voltage spikes in incoming power lines can damage electrical home appliances.

Type: zinc oxide arrester

Specifications:

- MOA rated voltage: 24kV

- MCOV: 19.5kV

- 1/4μs steep current impulse: 82kV

- 8/20μs lightning current impulse: 72kV

- 30/60μs switching current impulse: 62kV

- 2ms rectangular current impulse withstand: 150A

- 4/10μs high current impulse withstand: 65kA

Withdrawable trolley

Service trolley

Service trolley used for switchgears series KYN28-12 voltage 3 ~ 35 кВIEC 298.

It is best solution for VCB series VZN63-12 (VS1).